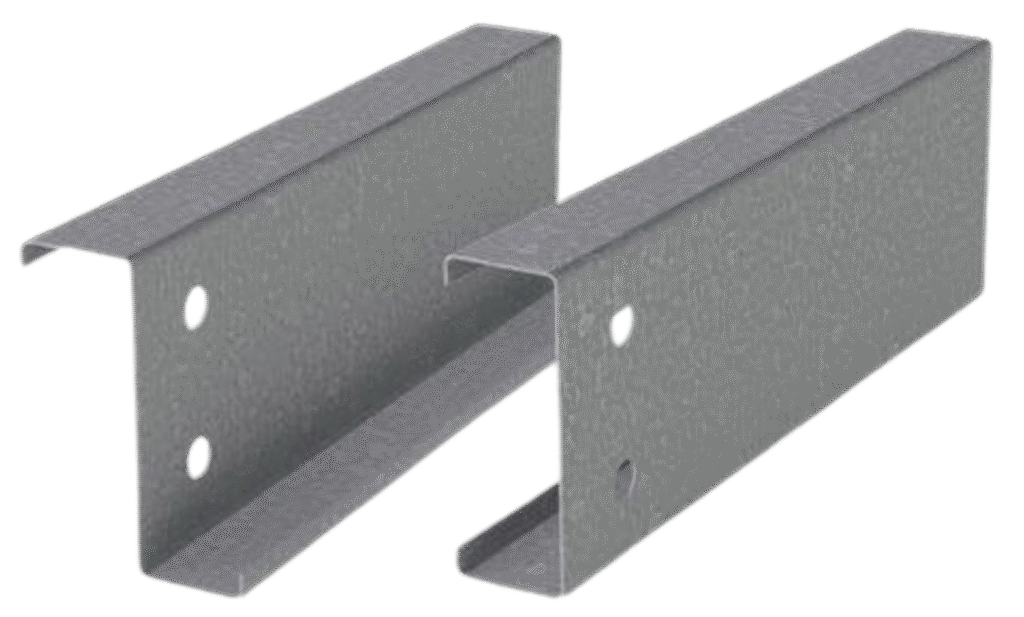

C & Z Purlin

Sri Amman Steels serve a wide range of C & Z purlins are roll formed from high tensile zinc coated steel. The cold roll forming process ensures a high degree of consistency and accuracy in the dimension of the sections. The C and Z purlins are Manufactured and supplied according to length and pre punched holes either round or elongated on the web and flange thus enabling immediate installation at site.

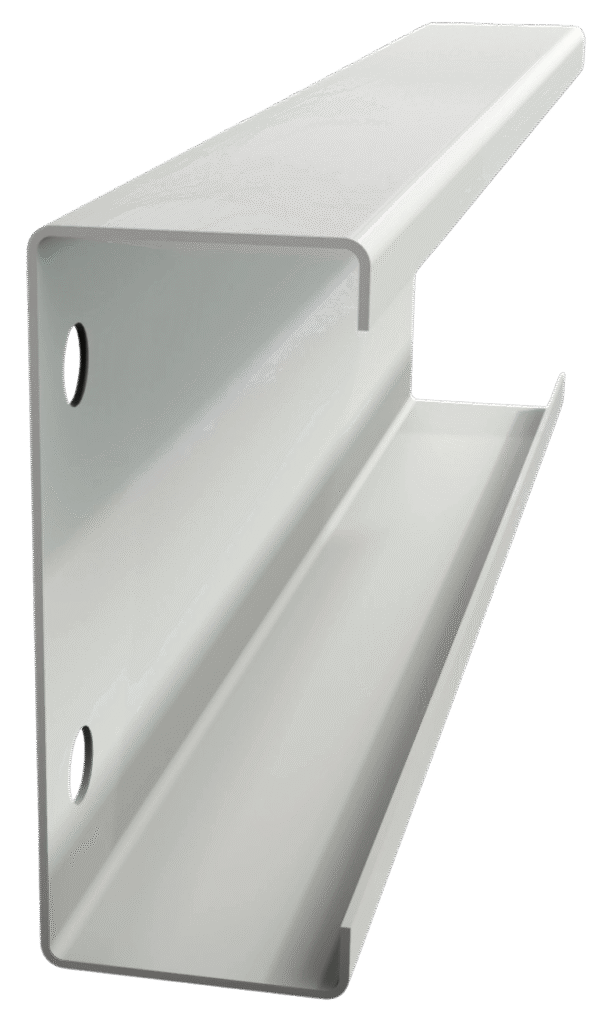

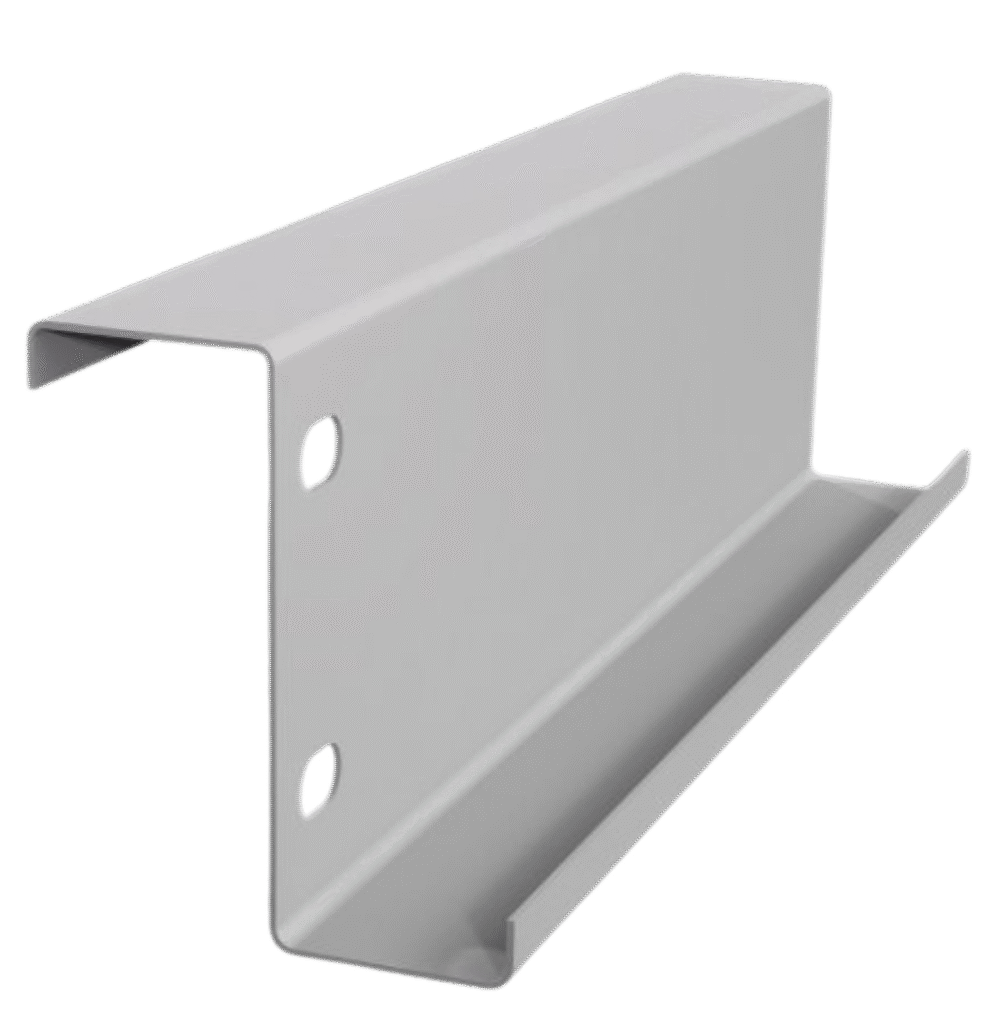

C Purlin

| Material | HR - JSW GI |

| Steel Grade | IS 2062 |

| Zinc Coating | 120 GSM, 180 GSM, & 275 Gsm |

| Thickness (mm) | 1.2 mm - 3.2 mm |

| Width (mm) | 80 mm - 300 mm |

| Flange width (mm) | 40 mm - 80 mm |

| Lip Size (mm) | 15 mm - 25 mm |

| Length (m) | Customizable |

| Yield Strength (MPa) | 240 MPa / 345 Mpa |

| Punching (Holes) | As per Requirement |

| Structural Shape | C shape |

| Weight (kg/m) | Varies based on size & thickness |

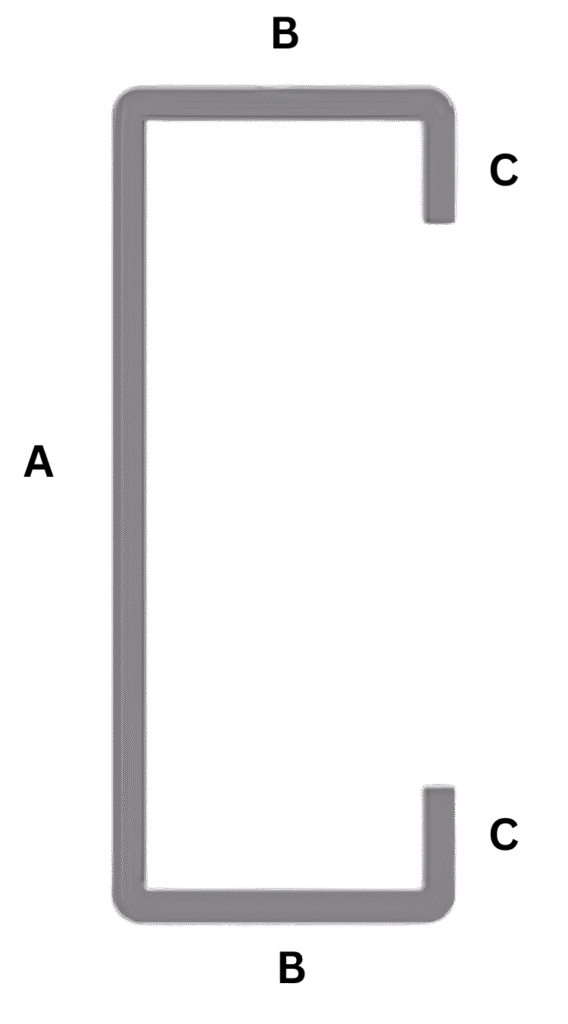

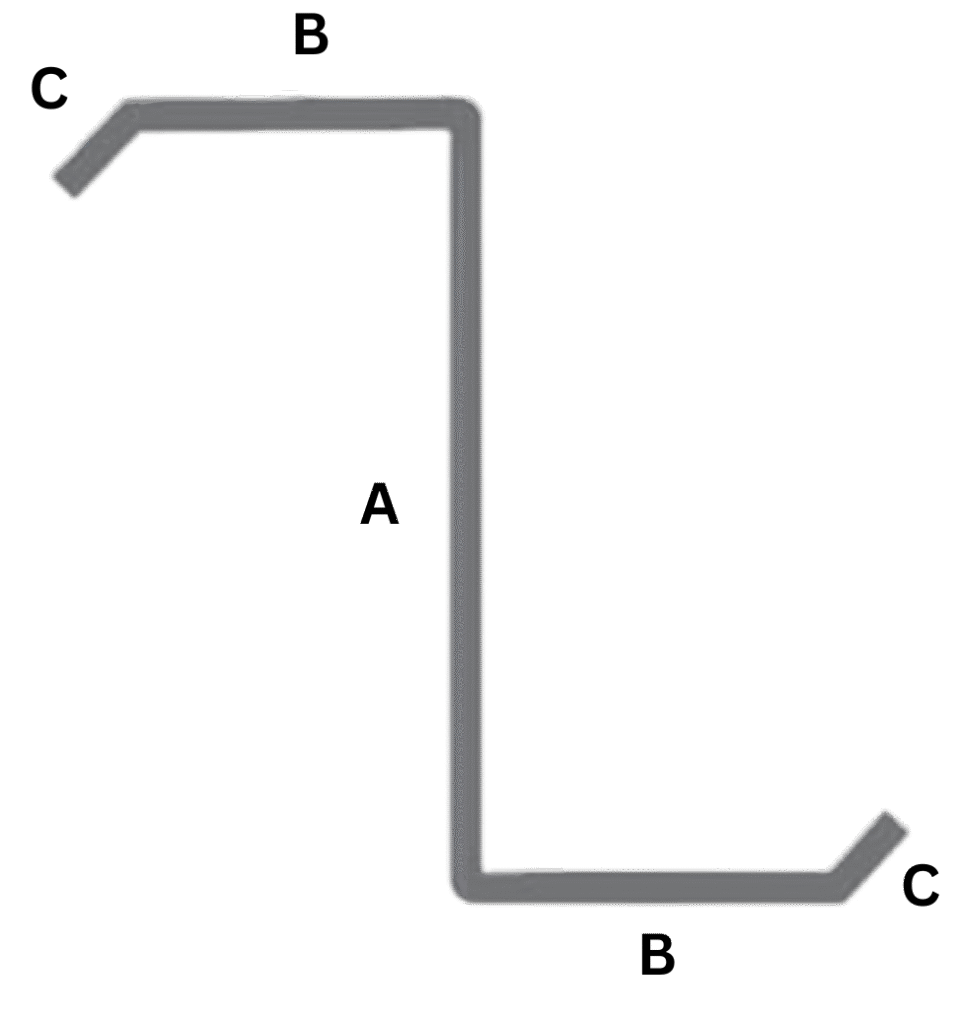

| Size | A | B | C |

|---|---|---|---|

| C100 | 100 | 40 | 20 |

| C120 | 120 | 40 | 20 |

| C150 | 150 | 60 | 20 |

| C180 | 180 | 70 | 20 |

| C200 | 200 | 60 | 20 |

| C250 | 250 | 70 | 20 |

| C300 | 300 | 75 | 20 |

Z Purlin

| Material | HR - JSW GI |

| Steel Grade | IS 2062 |

| Zinc Coating | 120 GSM, 180 GSM, & 275 Gsm |

| Thickness (mm) | 1.2mm – 3.2mm |

| Width (mm) | 100mm – 300mm |

| Flange Width (mm) | 40mm – 80mm |

| Lip Size (mm) | 15mm – 25mm |

| Length (m) | Customizable |

| Yield Strength (MPa) | 240MPa – 345MPa |

| Punching (Holes) | As per requirement |

| Structural Shape | Z-shaped |

| Weight (kg/m) | Varies based on size & thickness |

| Size | A | B | C |

|---|---|---|---|

| Z100 | 100 | 40 | 20 |

| Z120 | 120 | 40 | 20 |

| Z150 | 150 | 60 | 20 |

| Z180 | 180 | 70 | 20 |

| Z200 | 200 | 60 | 20 |

| Z250 | 250 | 70 | 20 |

| Z300 | 300 | 75 | 20 |

Applications

- Airports

- Commercial Buildings

- Indoor Stadiums

- Industrial Buildings

- Warehouses

Advantages

- High strength to weight Ratio

- Fastest Installation Time

- Economical & Low cost

- Greater Spanning Capacity

- Long Durability

Frequently Asked Questions

What are C and Z Purlins used for?

C and Z Purlins are structural members used in roofing and wall support systems. They're primarily used to support the load from the roof deck or sheeting and transfer it to the primary frame.

What’s the difference between C Purlin and Z Purlin?

C Purlins have a uniform “C” shape and are typically used for simple span applications.

Z Purlins have a “Z” shape, allowing them to overlap and be more efficient for continuous spans, which can reduce the number of supports required.

What materials are C and Z Purlins made from?

Purlins are made from high-quality galvanized steel (GI) or cold-formed steel, ensuring strength, corrosion resistance, and long-term durability.

Can I customize the size of the purlins?

Yes. We manufacture custom lengths, thicknesses, and sizes based on your project requirements. Standard sizes are also available for quick delivery.

How are purlins fixed to the structure?

Purlins are typically bolted or screwed to the rafters or wall frames using brackets, cleats, or fasteners—depending on the design of the structure.

What are the common thicknesses and sizes available?

We offer thicknesses ranging from 1.2 mm to 3.0 mm, and sizes starting from C100 to C300 or Z100 to Z300, depending on structural requirements.

Are C and Z Purlins suitable for all types of buildings?

Yes. They are commonly used in industrial sheds, warehouses, commercial complexes, and even in residential roofing where light steel structures are preferred.

Do purlins require painting or coating?

Our GI purlins are already coated with zinc, which provides corrosion resistance. However, additional painting or coating can be done based on environmental conditions or aesthetic preferences.

Can I use Z purlins instead of C purlins?

That depends on your design. Z Purlins are better for continuous spans and may offer material savings. Your structural engineer can suggest the best type based on your building load and layout.

How quickly can you deliver purlins after order confirmation?

We usually deliver within 3 to 5 working days, depending on the size and customization of your order. Our streamlined process ensures timely dispatch and delivery.